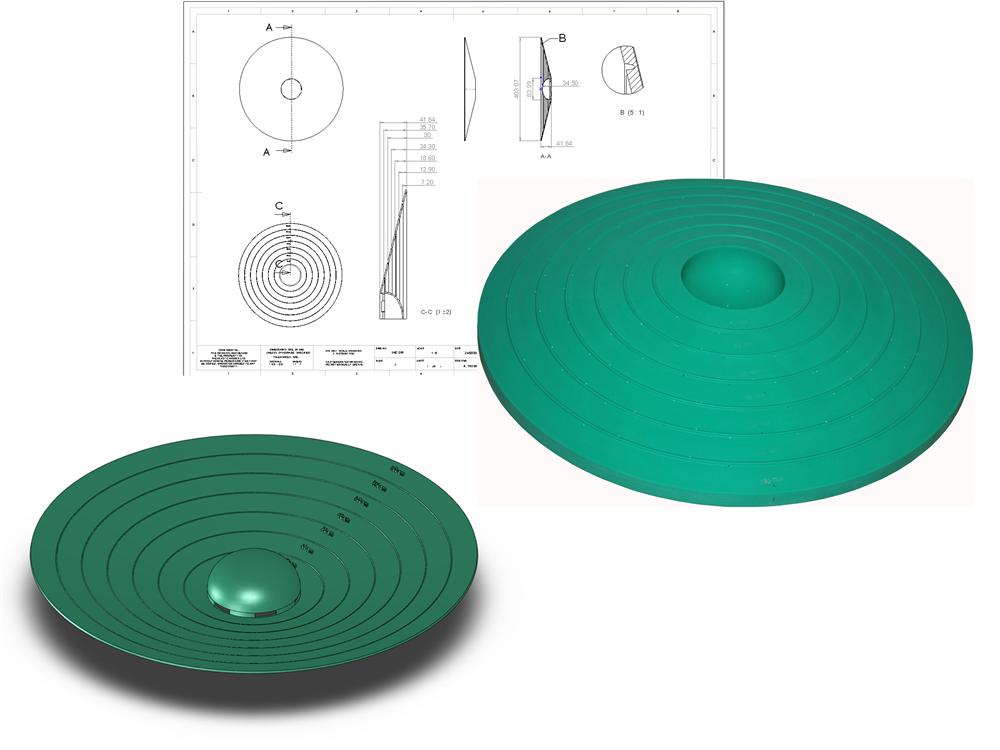

Prototype & Plastic Mold CompanyThe transition from concept and design to physical reality is possibly the most significant single step in the development of any product. This is the point at which an item which so far only existed on paper is given form, and can be measured, tested, and used. Prototyping gives designers the opportunity to address any real-world issues which arise and to plan for production of their product. To produce a true representation of a plastic product, it makes sense to partner with a prototype and plastic mould company with experience in producing both one-off samples and production runs which number into the thousands. The Plastic Works offer both CAD/CAM and traditional pattern-making routes to the production of moulds for creating vacuum formed plastic samples.

We can take your brief or virtual model, manufacture a prototype tool and using The vacuum forming process make a part reflective of what you would get at the manufacturing stage in both profile and dimension. But the choice of material type, texture, thickness and properties necessary, will be discussed and addressed before this stage along with any other requirements. This is why the plastic prototype manufacturing process requires experience and know how, as we can advise on what best suits your application in both material and design.

Any new product or other vacuum forming production project should not move on from the prototyping stage until all practical and aesthetic considerations are fully addressed. Even if this involves a protracted design refinement process with the production of many successive prototypes, we are happy to keep working with you until you get exactly the results you need. When a design project runs into obstacles, you need a prototype and plastic mould company with the expertise to think outside the box and suggest innovative solutions. We can bring to bear our experience working in all these diverse industries to find a way to bring your project to the production stage.  With our specialist knowledge of materials, these are some of the options available- A wide range of embosses & textures

- Colours

- Thicknesses

- UV stable

- Fire retardant grades

- Antibacterial additives

- Chemical resistance

Materials include:- ABS (flame retardant, antibacterial and textures)

- Acrylic capped ABS (for excellent UV and high gloss)

- Polyethylene and polypropylene (chemical, resistance)

- Polycarbonate (for high impact)

- HIPS (for sanitary applications)

- Speciality materials meeting fire, smoke and toxicity regulations.

|