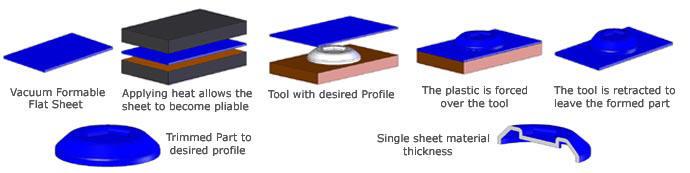

How Plastic Vacuum Forming Works

Plastic is an amazing material which can be moulded into almost any single thickness shape using the right techniques. When heated, the plastic becomes pliable and can be worked in various ways to achieve the desired profile. When cooled, the material retains the new shape and after trimming, is ready for use as a product or packaging.

The vacuum forming process includes the use of specifically shaped tools. Plastic sheets placed inside the plastic vacuum forming machine, and then heated until pliable. The machine uses vacuum to draw the air between the sheet and the shaping tool out to mould the plastic into shape. After it has cooled, the plastic can then be trimmed to the designed profile.

There are many types of plastic which are suitable for vacuum forming. A few are listed below:

Hips Vacuum Forming

High Impact Polystyrene is tough, light and inexpensive. It is often used for “Point of Sale” and sanitary applications.

Abs Vacuum Forming

Acrylonitrile Butadiene Styrene is one of the most common and versatile plastics in world industry. Because of its properties, with certain additives it can be flame retardant, UV stable, and even antibacterial. It can be used in applications from catering to heavy engineering, auto motive to Aerospace in varying colours and material finishes. You can even have an acrylic capping to give it that shiny gloss look.

Polypropylene Vacuum Forming

Some types of plastic are tough and durable under normal circumstances, but can be susceptible to changes in temperature and contact with certain chemicals. With Polyethylene and Polypropylene vacuum forming, these polyolefins are used in some of the world’s most demanding environments thanks to its specific polymer makeup.

Polycarbonate Vacuum Forming

Strong and transparent, Polycarbonate sheets are sometimes used as bulletproof windows. Yet this remarkable type of plastic can also be moulded by the vacuum forming process, to create useful shapes for many applications.

At The Plastic Works, we not only specialize in prompt volume production of vacuum formed plastic items, but we also have the facilities to prototype and produce tooling and moulds too. To find out more about plastic vacuum forming UK customers should contact The Plastic Works.