Plastic Product Design

The Plastic Works Ltd has plastic product design facilities to design your product to the specifications and aesthetics you require, using CAD (Computer Aided Design) we bring your ideas to life!

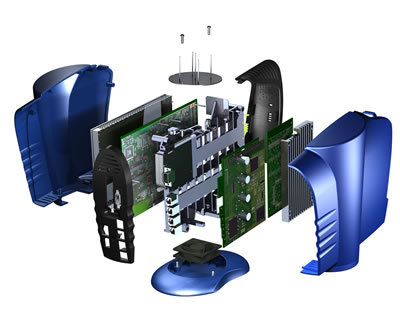

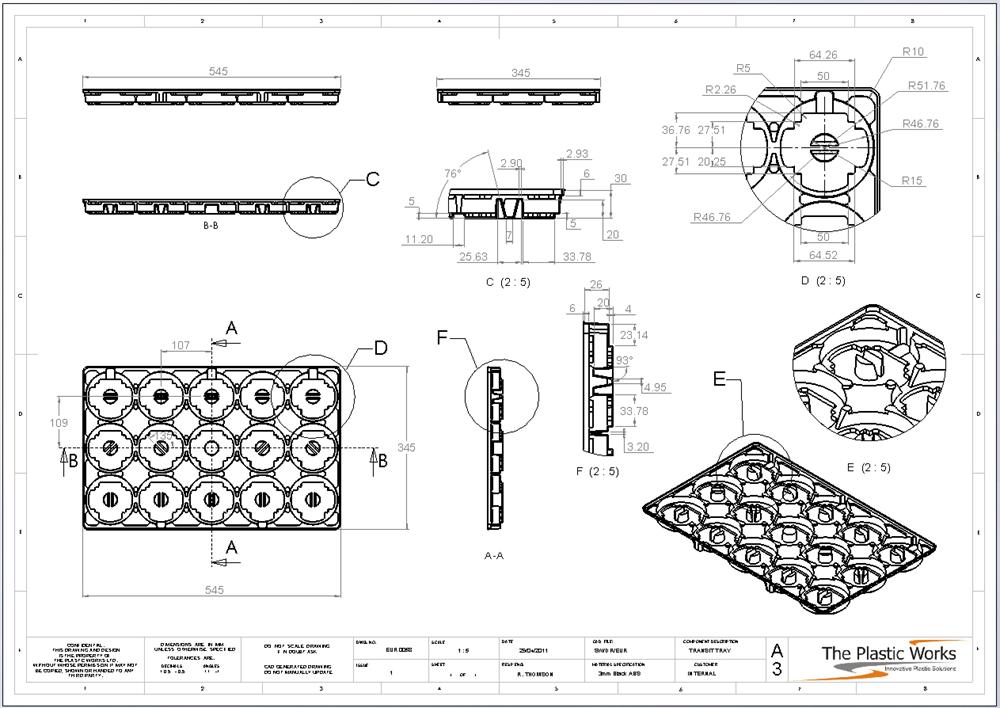

We take your initial ideas or preliminary sketches, mock up product or a simply a description of what you require, and using SolidWorks CAD technology we are able to produce 3D models and technical drawings – to ensure your product is Product Design Companies what you envisage before proceeding to manufacture. Solidworks is also capable of entertaining complex assemblies, so if your product is a combination of more than just one part, we can mate them together to make certain that there are no issues with collisions and that they assemble together correctly before any actual machining takes place.

We are able to generate both hard copy prints of the 3D model and technical drawings as well as being able to convert them into a format by which you can view them via e-mail like pdf. or jpeg.

We can also provide a fully interactive stand-alone program, which enables you to manipulate the 3D model, to view every aesthetical aspect of your product. This can also be used as an impressive presentation tool if so desired.

We are able to personalise products with Corporate or personal branding by using either embossed or depressed letters or images - creating a product that is distinctively yours!

Using CAD, we are also able to design out any inherent problems or improve the overall visualisation of the product. This facility saves time & money by finalising your product in the design stage before investing in prototypes & patterns.

Once you are completely satisfied with the plastic product design, we will then produce a pattern from that CAD Data by using either CAD/CAM (

Computer Aided Manufacturing

) or traditional pattern making (see Patterns & Tool making). Data is generated when creating the CAD model, which is then utilised to CNC machine the pattern / tool profile, which ensures both dimensional, and design accuracy - from which we will form a prototype.

Besides our all important innovative design service, we offer Technical Advice on Material Specifications, to best suit the application for which the product is designed. Certain materials have better impact strengths, resistance to cold, heat and chemical resistance, or simply just material colour variations and textures.

With our specialist knowledge of materials, processes and finishes, you can count on us for the best possible advice. With a broad range of thermoplastic materials available with differing characteristics, it is possible create a product which is suitable for most applications.

Such materials include:

-

ABS (flame retardant, antibacterial, varying gloss levels & textures)

-

Acrylic capped ABS (for excellent UV and high gloss)

-

Polyethylene and polypropylene (chemical, resistance)

-

Polycarbonate (for high impact)

-

HIPS (for sanitary applications)

-

Speciality materials meeting fire, smoke and toxicity regulations.

New Technology

Ongoing investment ensures a high standard of technology and services

Find out more about The Plastic Works - The

Vacuum Forming Company

|